Any member of the Australian Defence Force (ADF) that has completed initial training, exercises, or weapons training has more than likely fired blank ammunition. They have also likely had to correct the stoppages often incurred when firing such ammunition.

This article aims to explain some of the inherent issues with blank firing. It will provide details of weapon dynamics in order to allow operators and maintainers to better understand the function of these weapons, and how to diagnose and treat the symptoms.

ADF small arms are primarily designed to fire live ammunition; this is the nature of our job. Barrel length, distance from the chamber to the gas port, gas port diameter, and distance from the gas port to the muzzle are some of the key variables which must be balanced when designing a gas-operated weapon. Balancing these variables ensures there is sufficient pressure, at a specific time, for the weapon to cycle.

Different cartridges produce different weapon dynamics. To further explain the weapon dynamics, we will look at the design and gas pressure curve of the rifle, 5.56mm, Enhanced F88 (Thales F90-508 A1), referred to as the F90.

Live Firing

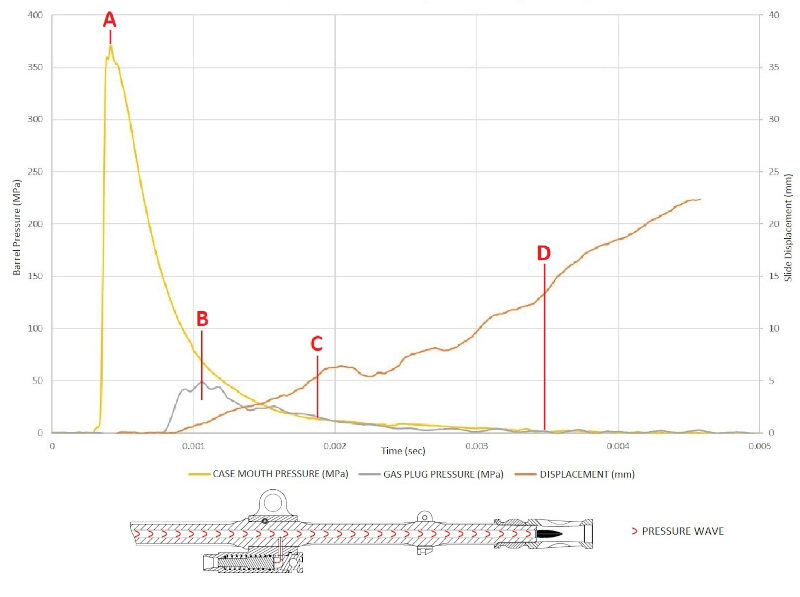

When firing live ammunition, the gas generated by the combustion of propellant serves two functions – to propel the projectile and to cycle the weapon action. At their peak, chamber pressures in the F90, when firing F1 Ball, reach approximately 375 MPa, or 55,000 psi (Figure 1, Point A).

This peak occurs relatively soon after ignition of the propellant, to rapidly accelerate the projectile. As the projectile moves down the bore, the volume filled by the gas expands, resulting in a corresponding decrease in pressure. As the projectile passes the gas port, some of the propellant gases are vented into the gas block, applying pressure to the gas piston.

The gas port experiences maximum pressures of approximately 48 MPa, or 6,960 psi (Figure 1, Point B). This pressure acts on the gas piston, causing it to impart rearward momentum to the slide sub-assembly. The pressure required to cycle the action is considerably lower than the pressure required to accelerate the projectile.

Throughout this entire process, the projectile effectively acts as a plug, containing the propellant gases within the weapon so that the gas system functions correctly. Once the gas piston has completed its full travel, all necessary momentum has been imparted to the slide sub-assembly for the weapon to cycle.

Figure 1 / Live Firing Pressure curve – F90

Once the slide sub-assembly has reached approximately 5.47mm of rearward travel, the angled section of the cam slot initiates rotation of the bolt, unlocking it from the barrel extension. As the bolt has completed unlocking, the barrel pressure has reduced to approximately 12 MPa, or 1,740 PSI (Figure 1, Point C). At approximately 12.73mm of rearward travel, the bolt is completely unlocked and commences extracting the cartridge from the chamber (Figure 1, Point D).

By this time, the projectile has already travelled the full length of the bore and exited at the muzzle, releasing all but 1 MPa, or 145 PSI of residual gas pressure.

Blank Firing

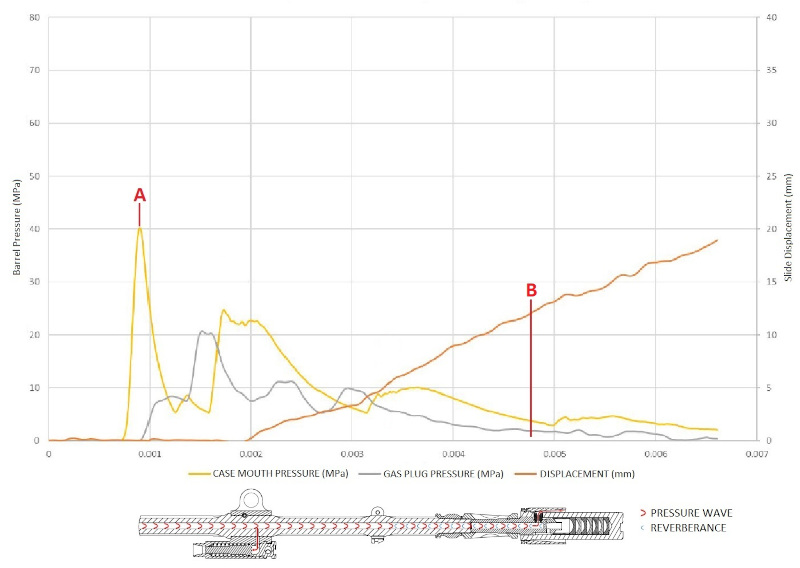

When firing F3A1 Blank (“blank”) ammunition, the gas is used to replicate the report of the weapon and to cycle the action. Peak gas pressures when firing blank are considerably lower than those produced with F1 Ball. This is due to two main reasons: there is no requirement to propel a projectile, and there is no projectile restricting the volume into which the gas can expand.

For the weapon to cycle correctly with blank ammunition, a Bullet-Trap Blank Firing Attachment (BTBFA) or similar device is required to contain the gas pressure.

The chamber pressure of the F90 reaches a maximum of approximately 40 MPa, or 5,800 psi, when firing F3A1 Blank ammunition (Figure 2, Point A). With no projectile to control the expansion of the gases, the entire barrel rapidly fills with gas.

Figure 2 / Blank Firing Pressure curve – F90

The gas is vented through the 1mm diameter gas jet orifice of the BTBFA and the 2.4mm gas port. In contrast, during live firing, the gas has a 5.56mm diameter opening for release of residual pressure (after the bullet has left the muzzle), and the 2.4mm gas port.

The BTBFA restricts the area the gas can vent to just 18% of that experienced during live firing. The effect of the BTBFA is a retention of residual gas pressure in the weapon, and the creation of pressure waves which reverberate up and down the barrel.

The pressure waves produce an uneven pressure drop (Figure 2). At the point of extraction (Figure 2, Point B), there is still around 4 MPa, or 580 PSI of residual gas pressure in the chamber – considerably higher than when firing F1 Ball.

Effects and treatment

In the F90, the slide locking controls when the bolt can and cannot rotate. During normal operation, the only time the bolt can rotate is when it is engaged with the barrel extension. Higher residual pressures in the barrel affects this function. As the bolt unlocks and begins to extract the blank cartridge, the residual pressure is released into the action. The pressure can cause a retraction of the slide locking and bolt into the slide sub-assembly (See comparison between Figure 3 and 4). Concurrently, the slide locking also retracts relative to the bolt.

This movement induces rotation of the bolt during ejection (termed “out-of-cycle bolt rotation”). The resultant effect is the ejection of cases on a tilted plane, causing them to strike the upper edge of the ejection port and/or buttstock interior. This impedes the case’s ejection and increases the frequency of failure-to-eject stoppages.

Figure 3 / Out-Of-Cycle Bolt Rotation with Poor or Failed Ejection

Figure 4 / Normal Bolt Rotation with Good Ejection Pattern

The rearward movement of the bolt also causes the bolt’s control pin to impinge on the inner corner of the slide locking’s cam slot. This produces a distinctive chipping of the component.

Out-of-cycle bolt rotation can be identified by inconsistent ejection patterns, with some cases ejecting normally, some cases barely clearing the action, and some cases striking the ejection port opening and deflecting down or back into the action, resulting in a stoppage.

Out-of-cycle bolt rotation can be mitigated, but not eliminated. As a first occurrence, maintainers are to inspect the BTBFA, ensuring the gas jet orifice is cleaned and gauged. If ejection port cover loss or obstructions continue, unit armourers / weapons technicians are to replace the slide locking, slide locking spring and ejector spring to reduce incidence of stoppages.

Suppressed firing

Use of suppressors with the F90 can produce similar dynamic effects to blank firing. As with blank, the condition of the slide locking sub-assembly and ejector spring should be monitored to mitigate dynamics issue.

Conclusion

Increased stoppages and contamination in the weapon experienced during blank firing is an inherent consequence of the different dynamics of blank firing and the optimisation of the weapon to fire live ammunition. Regular and targeted maintenance of weapons firing blank cartridges will mitigate observed issues; however, they cannot be eliminated.